HOW XS TESTING WORKS

An injector’s dynamic performance is comprised of three parts 1. Static flow and2. Linear operating flow3. Its opening non-linear flowAll XS injectors are tested to the J1832 standard which is the international engineers standard to ensure consistency in reporting.

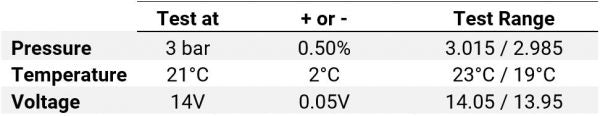

1. Testing Parameters

To make sure a test is repeatable every time, three parameters need to be tightly controlled. If any part of a test falls outside these parameters, we do not record it. It needs to be retestedTest controls

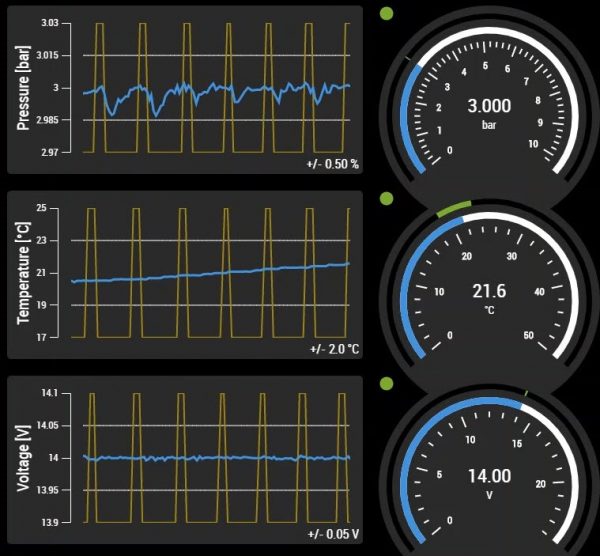

2. Test 1 - High Flow Sweep (Linear Range)

12 different duty cycles tested from 20% to 90% 100 flow test samples taken at each one (1200 results recorded) The average flow at each point is recorded The line of best fit is drawn through those points to get the injector slope Why we do this By calculating the injector flow slope, you know how the injector behaves from idle all the way through to flat out. By matching a set of injectors so that all of the injectors flow slopes (not just static flow) are within 1% of each other you have a set of injectors that flow exactly the same at idle, all the way through the rev range to open throttle. This gives a nice even fuel delivery across the whole set with no surprises. If you group injectors just on static flow rate they will all perform the same at the high end but will not be matched at the low end of the duty cycle. You will really notice this at cruise and idle.

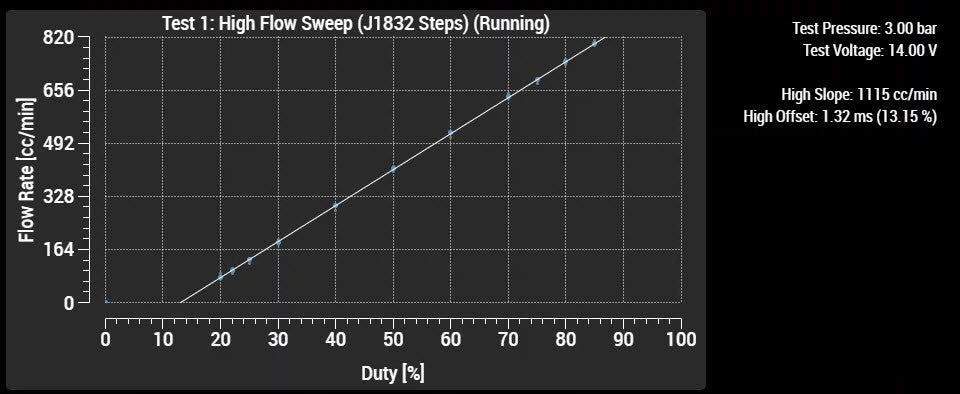

3. Test 2 - Static Flow Rate

The static flow rate of an injector is determined by holding the injector fully open (no pulsing) and measuring the total volume dispensed over a given time. The static flow rate is dependent on fuel pressure, the higher the pressure the higher the flow. The nominal flow rate of an injector is derived from its static flow rate at three bar pressure.

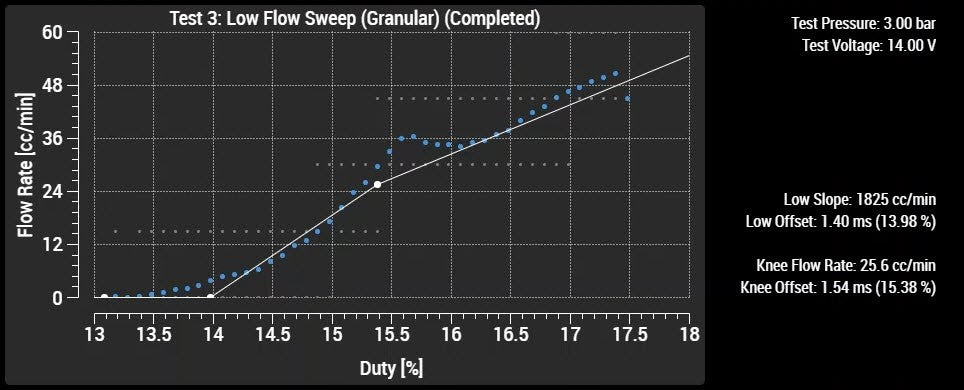

4. Test 3: Low Flow Sweep - Non-linear range

This is a very granular test and there are over 4000 flow tests recorded. Starting at very low duty cycles, we can see the exact point when fuel starts to come out of the injector and exactly how the injector flows up until the point that the flow becomes linear. With this test we can determine the injector offset (the point where fuel starts to come out) and the break point (or Knee). The break point is when the non linear range meets the linear range and the flow becomes a lot more predictable

5. Grouping injectors into tightly matched sets

After the injectors have been through testing, we run them through an algorithm to group them into tight sets. All dynamic flow rates must be within 1% of each other, then of those groups, the deadtimes must be within 2% of each other. You can log in at any time to see exactly how each of your injectors performed through the testing regime.

1800 615 6344

1800 615 6344

My Account

My Account